Knife Sharpening Angle Chart From Manufacturers

I have sought out manufacturer specifications to put together a knife sharpening angle chart. While a consistent angle is very important during the process, it’s helpful to know the original angle. That way you can maintain the knife characteristics as it was when new.

Jump down to Knife Sharpening Angle Chart

Consistent Knife Sharpening Angle

One of the secrets to sharpening a knife is maintaining a consistent knife sharpening angle during the process. Be it with a stone, or any other knife sharpening tool.

It’s much to do with the proper sharpening angle (degrees) and keeping it the same / consistent during the process.

Do you know the proper sharpening angle for your knife?

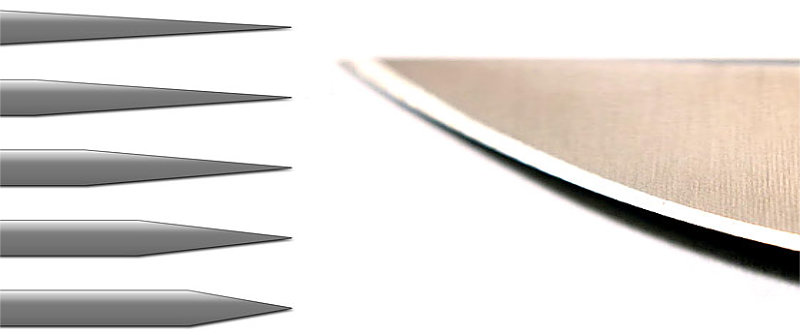

Knives have varying bevel angles. It depends on the manufacturer and model type.

Again, the following knife sharpening angles are based upon my own research, and I am not saying that this is all ‘absolute’. If you don’t have your original knife specifications, I feel confident the following information is a good place to start..

Common Sharpening Angles (degrees per side)

In general.. (more specific angles listed below)

Pocket Knives – 20

Hunting Knives – 22

Tactical Knives – 22

Kitchen Knives (Euro/American) – 20

Kitchen Knives (Asian) – 16

Fillet Knives – 16

Custom Knives – Varies by Designer

Smith’s Adjustable Angle Knife Sharpener

One quick-and-easy way to restore a sharp cutting edge is to use an adjustable knife sharpener. Simply select the same angle as your knife edge. 14,16,18,20,22,24 degrees.

It’s an alternative to having a fixed angle or guided knife sharpener. Among the different types and techniques of sharpening, I also have (and use) the following ‘quick’ sharpener from Smith’s.

Smith’s 50264 Adjustable

(view on amzn)

Lansky QuadSharp with Preset Knife Angles

I also like the Lansky QuadSharp with its convenient form-factor. It has presets for 17, 20, 25, and 30 degree knife angles.

What’s really neat is its ability to sharpen the serrated notches of a knife. A few of my pocket knives are half-and-half, flat blade with a serrated section.

Lansky QuadSharp QSHARP

(amzn)

Knife Sharpening Abrasives

Types of sharpening abrasive materials include Diamond, Carbides, Ceramics, Arkansas Stones, and Synthetics. Each have their own unique characteristics and sharpening capabilities:

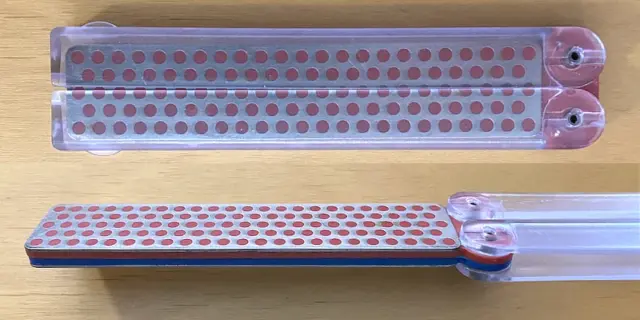

Diamond Sharpener

Because diamonds are the hardest substance known to man, diamond abrasive knife sharpeners are fast, durable, and very effective.

They are very aggressive and remove metal quickly.

Premium diamond sharpening surfaces are characterized by a (interrupted) surface that collects and hold the metal filings that ordinarily build-up.

This allows sharpening with or without honing solution. Excellent for use on very hard tools or stainless steel.

Diamond stones always remain flat, as opposed to Natural Arkansas and Synthetic stones which wear down with use. They come in multiple grits.

Carbide Sharpener

Carbide is very aggressive and removes metal quickly.

It’s great for quickly restoring a good working edge in 3 or 4 strokes.

Ceramic Sharpener

Unlike other sharpening abrasives, Ceramic removes very little metal.

It’s excellent for finishing and maintaining a sharp edge.

Ceramic (and ceramic sharpening rods) come in various grits, colors, and shapes.

Arkansas Sharpening Stones

Arkansas stones are genuine silica “novaculite,” indigenous to Arkansas.

They remove the least amount of metal while polishing your edge to razor sharpness.

No other knife sharpener can perform both these tasks simultaneously. They are the best abrasive for honing and polishing an edge to razor sharpness and are known as “the world’s finest finishing stone.”

Synthetic Knife Sharpeners

Purpose-made stone; great for quick edge setting as well as final finishing. They also come in multiple grits, colors, or shapes.

Knife Manufacturer Sharpening Angles

Knife Sharpening Angle Chart (data from manufacturers)

Wondering what angle to sharpen your knife? It’s best to check with the manufacturer. Here’s a chart with sharpening angles from a number of various manufacturers.

Tip (when you don’t know what sharpening angle to use), Use whatever angle most closely matches the one already established on the original factory edge.

DPS (degrees per side)

Chef’s knife:

Global – 17

Shun – 16

Wusthof – 14

Zwilling Henckel / Cronidur – 12.5

All other Zwilling Henckel – 15

Serrated Knife:

All Brands – Manual Sharpening; Serrated Slot ONLY

Santoku Knife:

Global – 17

Shun – 16

Wusthof – 11

Zwilling Henckel / Cronidur – 12.5

All other Zwilling Henckel – 15

Paring Knife:

Global – 17

Shun – 16

Wusthof – 14

Zwilling Henckel / Cronidur – 12.5

All other Zwilling Henckel – 15

Utility knife:

Global – 17

Shun – 16

Wusthof – 14

Zwilling Henckel / Cronidur – 12.5

All other Zwilling Henckel – 15

Boning Knife:

Global – 17

Shun – 16

Wusthof – 18

Zwilling Henckel / Cronidur – 12.5

All other Zwilling Henckel – 15

Everyday Pocket Knives/Multi-Tools:

Al Mar – 20

Benchmade – 18-20

Blade-Tech – 20-22

Boker USA – 20-22

Buck – 13-16

Camillus – 23

Case – 19-22

Cold Steel – 23-25

Columbia River (CRKT) – 17-22.5(depending on designer)

KA-BAR – Listed on their website on a per knife basis, but generally 15 degrees per side

Kershaw – 20-22

Knives of Alaska – 18-20

Outdoor Edge – 20

SOG knife sharpening angle – 22 for flat grinds; 18-20 for hollow grinds

Spyderco – 20

Victorinox – 15-20

Winchester – Suggest using Smith’s recommended angle for knife type

Hunting/Outdoor – Fixed Blade:

Al Mar – 20

Benchmade – 18-20

Blade-Tech – 20-22

Boker USA – 20-22

Buck – 13-16

Camillus – 23

Case – 19-22

Cold Steel – 23-25

Columbia River (CRKT) – 17-22.5(depending on designer)

KA-BAR – Listed on their website on a per knife basis, but generally 20 degrees per side

Kershaw – 20-22

Knives of Alaska – 18-20

Outdoor Edge – 20

SOG – 22 for flat grinds; 18-20 for hollow grinds

Spyderco – 20

Winchester – Suggest using Smith’s recommended angle for knife type

Hunting knives / Folders:

Al Mar – 20

Benchmade – 18-20

Blade-Tech – 20-22

Boker USA – 20-22

Buck – 13-16

Camillus – 23

Case – 19-22

Cold Steel – 23-25

Columbia River (CRKT) – 17-22.5(depending on designer)

Gerber – 15 (apparently all Gerber knives angle at 15 degrees)

KA-BAR – Listed on their website on a per knife basis, but generally 15 degrees per side

Kershaw – 20-22

Knives of Alaska – 18-20

Outdoor Edge – 20

SOG – 22 for flat grinds; 18-20 for hollow grinds

Spyderco – 20

Winchester – Suggest using Smith’s recommended angle for knife type

Fillet Knives:

All Brands – 15-16

Tactical Knives:

Al Mar – 20

Benchmade – 18-20

Blade-Tech – 20-22

Boker USA – 20-22

Buck – 13-16

Camillus – 23

Case – 19-22

Cold Steel – 23-25

Columbia River (CRKT) – 17-22.5(depending on designer)

KA-BAR – Listed on their website on a per knife basis, but generally 15 degrees per side

Kershaw – 20-22

Mil-Tac – Generally 25 for Folders and 30 for Fixed Blades

SOG – 22 for flat grinds; 18-20 for hollow grinds

Spyderco – 20

Surefire – 28

Custom Knives:

A.G. Russell – 15

Chris Reeves – 18-20

William Henry – 17-22

Reader Tips:

- Run the blade through the same number of sharpening strokes on EACH side. NEVER do more on one side.

- Personally I find maintaining the edge with a strop and once every few uses a ultra fine stone or plate is best, just easier to maintain rather than restore.

- If you have very sharp kitchen knives, some guests that come over may need to be warned about your sharp blades. A sharp knife is a safe knife – but some people still need to be warned :-)

Diamond & Ceramic Rods

A knife sharpening rod works great due to the fact that every blade has a different degree of bevel or angle.

The rod allows you to let the edge guide you, while keeping the rest of the knife away from the sharpening device.

A diamond rod is for a knife blade with serious damage or very dulled blade.

The ceramic rod is for “freshening up” a dull-ish blade. I keep one on my bench as well as in the kitchen and field pack.

I use the following knife sharpening rods:

Lansky Tactical with Diamond Carbide Rod

(view on amzn)

The Lansky LCD02 has a 40 degree angle (20 degrees each side) (I measured it).

Sharpening a knife to razor edge with a Strop

This is the process in “how to sharpen a knife” where you can get your knife RAZOR SHARP!

Leather Strop

(view on amzn)

Here’s my leather strop, clipped on to a screw-eye attached to a wall (or whatever). That way you can pull it tight while stropping your knife for that razor edge.

This is the last step in the process of sharpening knives.

Stropping is a motion which pulls the cutting edge away from a substrate.

The direction of stropping strokes:

Drag the edge backwards over the strop. In other words, it’s a “trailing stroke” by pulling the knife edge rather than “leading strokes” (as you would with a stone or rod).

Use a light touch and maintain the angle of the knife edge.

Alternate sides with each stroke.

Use Stropping Compound to further enhance results:

Extra Fine Buffing Compound

(view on amzn)

How to Sharpen a Pocket Knife by Hand

Here’s one way.. The basic technique to sharpen kitchen knives and a pocket knife is the same as the steps listed above!

Here’s a basic method to sharpen a knife! It works!

Sharpening my pocket knife:

The portable knife sharpener shown in the picture is one that I often use.

It has microscopic diamonds embedded in each of the two sides (one side is finer grit than the other).

Double Sided Diafold

(view on amzn)

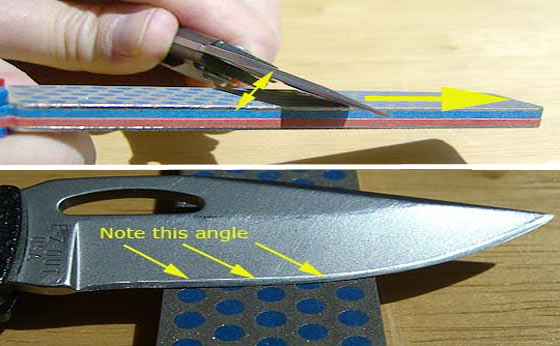

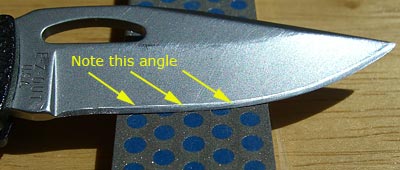

Sharpening Technique:

Hold the knife against the sharpening stone at the same angle as the sharpened edge itself. Then push it forward across the sharpening tool while maintaining that same angle.

After sliding the knife across the stone, don’t slide it back up against the stone… Lift the knife and start over from the top of the knife sharpener and slide it down across its surface again.

More specifically, you should sweep the knife such that you are contacting the entire surface of the blade in one arcing motion down the sharpening tool (therefore sharpening evenly). The longer the blade, the more dramatic the sweep, so as to get the entire blade in one smooth motion.

You will get into a steady rhythm while practicing. Apply light to moderate pressure.

Maintain The Angle

The key when sharpening by hand (without a jig) is to hold and maintain the knife blade at the proper angle.

To determine that angle, it may help to first rest the knife on the edge of the stone. Look closely at the blade’s sharpened edge. Then adjust the knife’s angle until you see that the sharpened edge sits ‘flat’ against the knife sharpener tool’s surface.

Once you’ve visualized the proper angle, just go with it…

Without getting into the various differences in proper angle, suffice it to say that ‘typically’ that angle is somewhere around 20-degrees.

So one trick is to first hold the knife at a 45-degree angle against the sharpening tool (easy to visualize) and then adjust the knife to half that angle, which will be close to what you want.

[ Read: Your Favorite Small Pocket Knife ]